Automatic Bag Slitting Machine

- Client: Aarti Industries Limited

- Supply: Automatic Bag Slitting Machine

- Material: Customised Materia

- Location: Vapi, Gujarat

Description of Supply:

- Automatic Bag Slitting Machine supplied to remove the Human interaction with the Hazardous material.

- Automatic Bag Slitting Machine Cut the Bag and transfer the material towards the defined utility as per requirement.

- First the bag passed through the belt conveyor and transferred to the Bag Slitting Unit.

- Bag Slitting Unit will cut the bag and unload the material in to the Material Hopper.

- Material Hopper consisting of a vibrator to make proper unloading and it will further pass the material to Weighing Hopper as per requirement.

- After the material collected in weighing hopper it will further conveyed to the defined utility.

- At the time of slitting, if the material is in powder form it will start shattering in to the drum surround. This shattered material is collected by Dust Collector provided on the Top of the Bag Emptying Unit and re-purge in to the drum itself.

- Dust Collector Consisting of number of Filter Bags of customised material and automatic purging system equipped with actuated valves will throw the pressurised air and clean the Filter Bags. The material removed from the Filter Bags is emptied into the Bag Emptier so, there is no material waste occurs during the process.

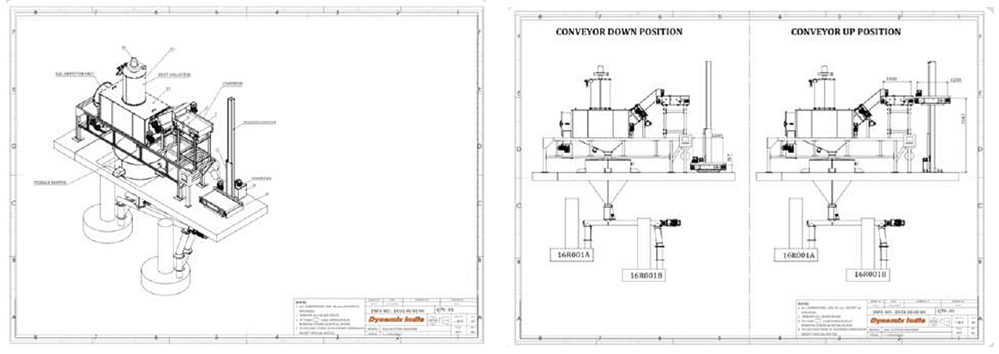

Drawing:

Equipment / Instruments use for Automatic Bag Slitting Machine:

- Bag Transfer Conveyor

- Bag Slitting Unit

- Bag Emptying Unit

- Material Storage Hopper

- Dust Collector

- Bag Compactor

- Weighing Hopper

- Actuated Rotary Airlock Valve

- Control Panel